Tablet De-Duster for Tablet Press Unit

Tablet De-dusting and De-burring Process

Application

De-Duster is pharmaceutical processing equipment that removes the fine surface dust from tablets by using a vibratory effect. This machine can be linked directly to any type of high-speed tablet press.

In Elevating Dedusterthere are vibrated uphill type sieves. The tablets enter the bottom inlet of perforated sieve from directly Tablet Press then they are gently vibrated and the tablet to move forward, upward, turning and rotating along the spiral up hill path of the perforated plate to outer at top of the sieve.Inspiral deduster there is vibrated spiral path perforated sieve. The tablets enter in centre of perforated sieve from directly Tablet Press then they are gently vibrated and the tablet to move forward, turning and rotating along the spiral path of the perforated plate to outer peripheries.

Features

- All contact parts AISI 316 & non-contact parts AISI 304.

- Geometrically designed tablet route to ensure remove dust and burrs.

- Easy to install with all types of Tablet Press with an inline metal detector.

- Option for Spiral OR Elevating-Up hill type Deduster.

- Adjustable height.

- Easy and simple dismantle for cleaning of all contact parts.

- Design is cGMP – Current Good Manufacturing Practices compliance.

Dust Extractor

Application

The Dust Extractor unit is used for controlling dust in process of Tabletting and packing. The unit strongly recommends the use of dust control equipment with all Tablet press and De-duster.

Dust laden air enters the collector through an expansion chamber, where heavy dust particles are deposited by gravity. The fine dust passes upwards through the single large orifice and is finally collected by a filter.

FEATURES

- Design is cGMP – Current Good Manufacturing Practices compliance.

- All contact parts AISI 316 & non-contact parts AISI 304.

- Easy to connect all types of Tablet press and De-Duster.

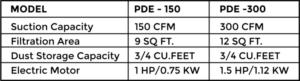

Technical Specification

Tablet Metal Detector

Metal Detector for Tableting

Application

The metal detector is designed for the detection and removal of minute pieces of ferrous, nonferrous, and stainless steel contaminations in tablets. This metal detector removes metallic contaminants automatically and without production interruption from a stream of tablets. The metallic contaminant is reliably rejected with very little loss of material due to the extremely fast and short activation of the reject flap. The metal detector chute can be quickly and easily dismantled for routine cleaning and product changeover. Flexible operating height, angle, and frame with lockable castor to allow for easy integration to any production facility.

The Metal detector incorporates a simplified and refined design of the automatic Balance Coil Principle, which eliminates all setting up controls and permits long consistent performance.

Features

- The Machine construction and components in accordance with cGMP standard.

- All contact parts AISI316 Quality and Non-contact parts AISI304 Quality.

- Manual set up of sensitivity all other parameters through potentiometers.

- Easy to install and operate.

- Easy changeable electronic module.

- Easy to cleaning and movability.

- Solid-state relays for arc-free switching.

- Adjustable height Single pillar stand with 4 nos castor wheel.

- Food grade nonmetallic white chute.